Bending the Rules

Technical manoeuvring to push regulatory boundaries for the slightest performance edge without actually breaking any rules is a familiar pattern in all forms of motorsport. Engineers treat the rule book less as rigid regulations and more as a puzzle to be solved, and we have time and again seen race-winning innovations emerge from the grey area between the letter and the spirit of the law. Benetton’s 1994 traction control workaround, the double diffuser introduced by Brawn GP in 2009, Red Bull’s 2010 flexible wings that stayed rigid during static load tests but flexed at high speed, and Mercedes’ dual-axis steering that allowed drivers to fine-tune wheel alignment on the fly are well-known examples of this trend over the decades.

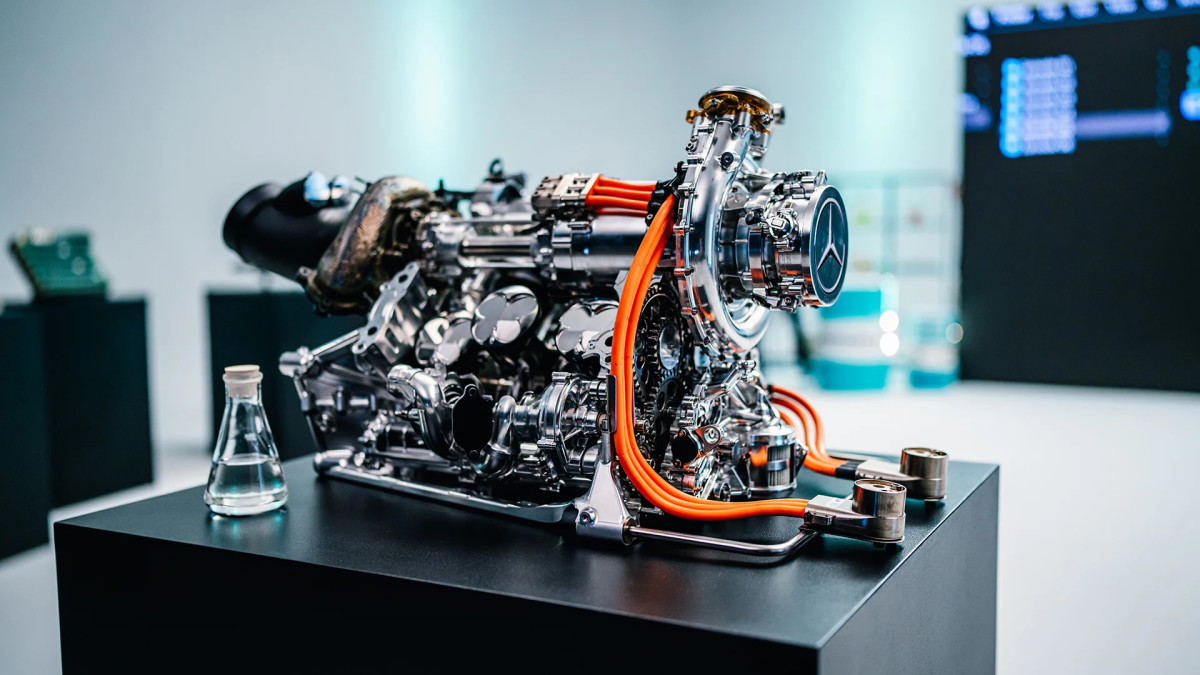

Now, for the 2026 season, Mercedes and Red Bull seem to have found a way around the new compression ratio cap that has dropped the maximum allowable compression ratio from last year’s 18:1 to 16:1. While higher compression means more power, it also drives up heat, complexity, and stresses on the engine, leading teams to spend massive amounts of money trying to develop and build engines that can survive these rigors. The 16:1 ceiling was introduced to reduce development complexities for new teams and level the playing field.

The Loophole

The FIA measures the static geometric compression ratio based on an engine’s maximum cylinder volume with the piston at bottom dead center, and minimum volume with the piston at top dead center, all while the engine is at ambient temperature. However, at high temperature and high rpm, pistons expand, and rods stretch, slightly altering the compression ratio. Mercedes and Red Bull are trying to use this to their advantage by manufacturing pistons with complex internal structures designed to maximize and optimize thermal expansion, boosting compression when the engine is at operating temperature.

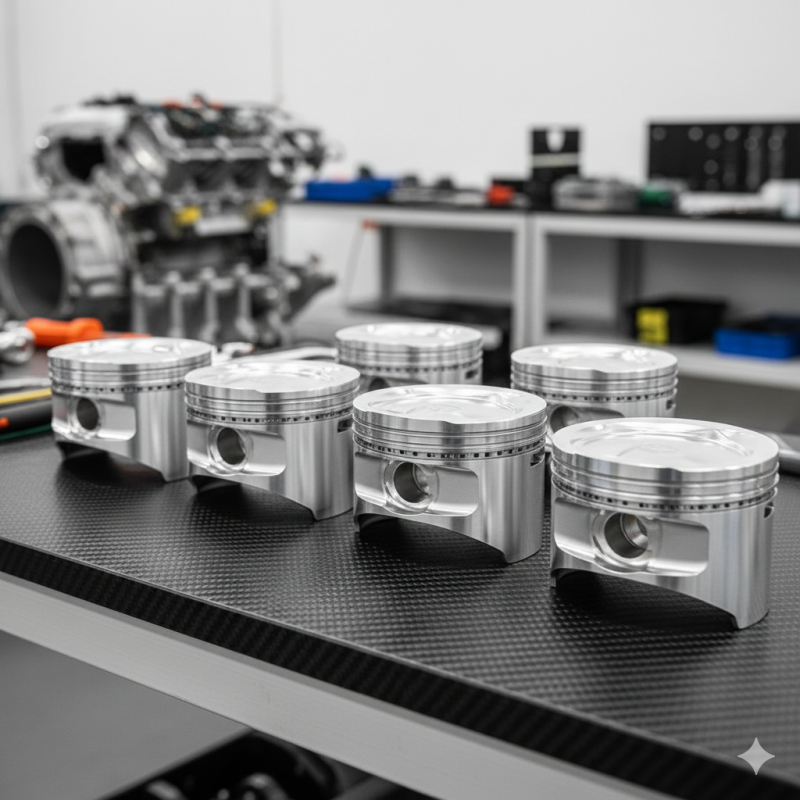

3D-Printed Pistons

F1 pistons are made of a steel alloy, and race teams over the last few years have gone from the subtractive manufacturing process of forging pistons from steel billet, to the additive manufacturing process of 3D printing using highly powerful and precise lasers. This allows teams to incorporate complex structures within solid metal parts and even adjust the density of the material throughout each part. Engineers at Mercedes and Red Bull have used this precise control over the internal architecture of the piston to engineer a structure that can channel the heat generated from combustion to certain specific points to cause the piston expand more than it would, were it milled from a solid block.

The Bottom Line

If Mercedes and Red Bull have truly succeeded in creating pistons that expand enough to offer an appreciable compression ratio boost, they could start off the season with a substantial power advantage over the rest of the field. In a sport where championships are decided by fractions of a second, a few horsepower more could play a significant role in the year’s proceedings. Rival teams Ferrari, Audi, and Honda have written a joint letter to the FIA seeking clarification about the engine regulations, and requesting a method be employed to measure the compression ratio when the engines are at operating temperature. However, with the season set to kick off on March 8, it seems unlikely that we will see a change in the rules before then.