Built Like a Brick

The Jeep 4.0-liter inline-six, also known as the AMC 242, may not have been the most powerful engine of its era – especially compared to Toyota’s 4.0-liter V6, which produced around 245 horsepower – but it made up for that with a reputation for durability. However, like most engines, the Jeep 4.0 can develop serious issues if neglected, as shown in this particular example that Eric from I Do Cars tore down.

Based on the part numbers for the upper radiator hose and distributor, this engine was believed to have been sourced from a 1998 Jeep Grand Cherokee, which was rated at approximately 185 horsepower and 220 lb-ft of torque. It was also offered with a more potent V8 engine. The engine specialist didn’t have any background on it – no mileage, no service history, and no clear explanation of how it failed. However, early signs, such as visible holes in the oil pan, already suggest the damage was catastrophic.

Inside the Damage

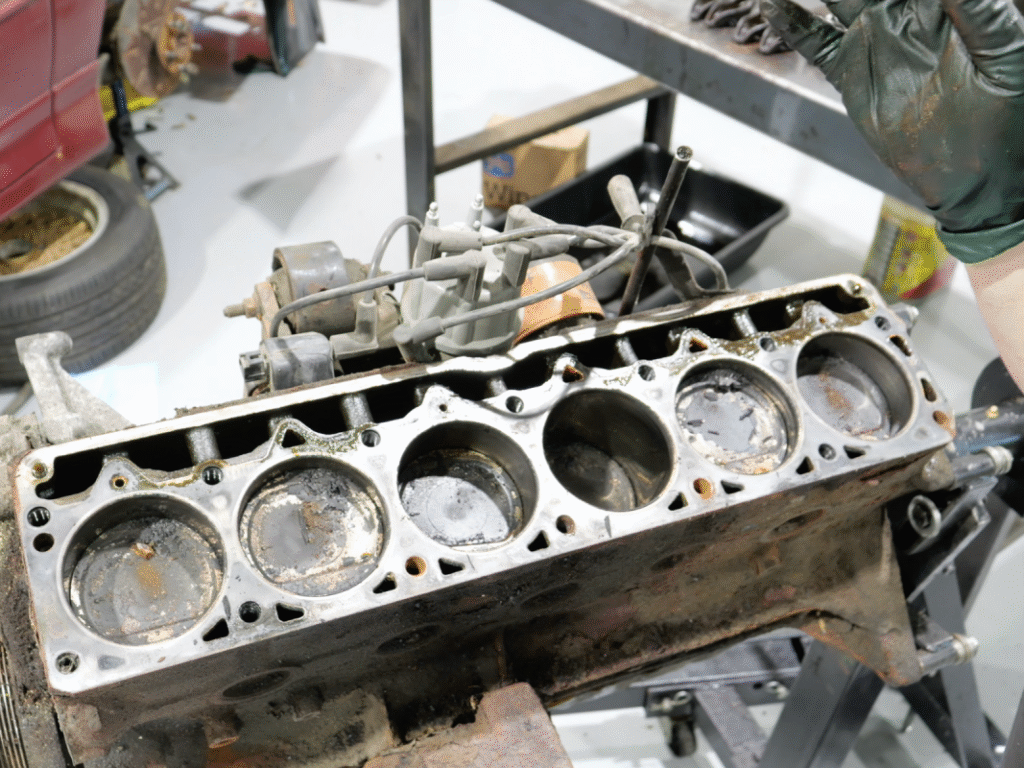

After removing the valve cover, the valvetrain components initially appeared to be in fair condition. However, the oil was contaminated with metal shavings and traces of coolant fluids that should never mix, indicating severe internal failure. Further inspection of the block revealed heavy carbon buildup on top of the cylinders, and one piston crown showed visible cracking.

Unsurprisingly, the oil pan contained significant engine debris, including pieces of a connecting rod and a wrist pin, a part usually not found in the oil pan. There were also impact marks on the crankshaft, while most of the bearings were in bad condition.

Tough, But Not Untouchable

This Jeep 4.0 showed clear signs of having run with low oil. Without adequate lubrication, internal components make metal-to-metal contact, accelerating wear and raising operating temperatures. As heat builds, the risk of catastrophic failure increases – often resulting in a “grenaded” engine, where internal parts break apart and punch through the block or oil pan. Eric also noted that the engine appeared to have been rebuilt at some point based on the parts used, suggesting it had already experienced serious issues prior to this failure.

The takeaway is that the classic Grand Cherokee powerplant didn’t fail due to a design flaw. It used a simple pushrod layout with a cast-iron block and cylinder head – an inherently durable setup capable of lasting around 300,000 miles with proper maintenance.