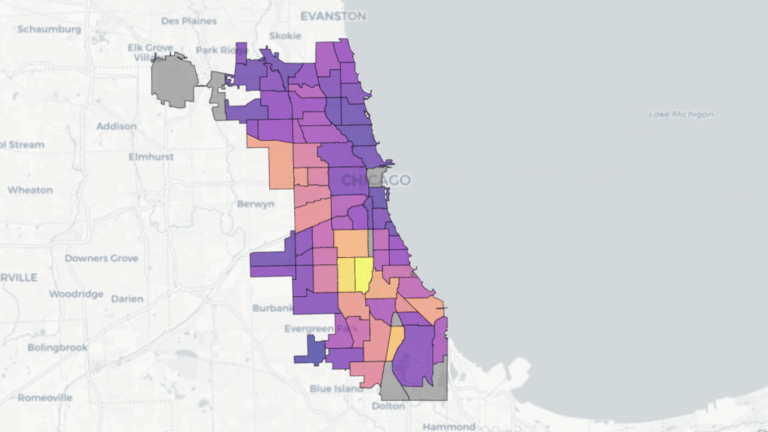

Across North America, abandoned oil and gas wells are leaking carbon dioxide and other greenhouse gases into the atmosphere. As of 2022, there were more than 123,000 documented orphaned wells in the United States, but researchers suspect the real number may be anywhere from 310,000 to 800,000.

Abandoned wells can be plugged by filling the drill holes with water or oil, but that process requires a substantial amount of liquid, as well as liquid assets. It would take 26 billion gallons—an amount that would fill almost 40,000 Olympic-size swimming pools—to plug 120,000 wells, with each well costing up to $1 million. (That’s $120 billion in total.)

“On the one hand, you have these underutilized waste products. On the other hand, you have abandoned oil wells that need to be plugged. It’s an abundant resource meeting an urgent demand.”

In a new study published in Energy Conversion and Management, researchers weighed the possibility of plugging wells and sequestering carbon with bio-oil made from vegetative waste. Their goal was to see whether the production of bio-oil could be a source of revenue for farmers while the oil itself could prevent greenhouse gases from escaping from abandoned wells.

“On the one hand, you have these underutilized waste products,” explained Mark Mba-Wright in a statement. Mba-Wright is a coauthor of the new paper, engineering professor at Iowa State University, and systems engineer at its Bioeconomy Institute. “On the other hand, you have abandoned oil wells that need to be plugged. It’s an abundant resource meeting an urgent demand.”

Biomass Bounty

The production of bio-oil starts with pyrolysis, the process in which vegetative waste decomposes under intense heat (≥1,000℉, or ~538°C°) in an oxygen-free environment. Pyrolysis produces three products: a liquid (bio-oil), a solid (biochar), and a gas. The gas is used to fuel future pyrolysis efforts, biochar can be sold as a soil amendment, and storing bio-oil underground has long been touted as an effective way to sequester carbon.

The fields and forests of the United States are ripe with plants and thus vegetative waste that could be used to produce bio-oil. For example, “for every kilogram of corn that the farmer produces, an additional kilogram of corn stover or biomass is produced,” said Mba-Wright.

Corn stover—the stalks, husks, and cobs left over after harvest—is a leading source of biomass for Midwestern farmers. In the western United States, woody forest debris is more widely available. To address this diversity of resources, Mba-Wright and his colleagues investigated the bio-oil potential of corn stover, switchgrass, pine, tulip poplar, hybrid poplar, and oriented strand board (an engineered product made with wood flakes and adhesives).

In partnership with Charm Industrial, a private carbon capture company, Mba-Wright and his colleagues sought to understand whether corn stover and other feedstocks would be suitable for bio-oil production, whether the process would be economically helpful to farmers, and whether the processing-to-plugging pathway would be effective at sequestering carbon.

Small-Scale Pyrolysis Feasibility

Charm has been using pyrolysis at a commercial scale for years, said Mba-Wright, but building large plants requires significant capital investment and risk.

Instead of a large, stationary plant, the team modeled the environmental and economic feasibility of an array of mobile pyrolysis units that could be located on farms. “You can imagine a farmer might be using his tractor or his combine on his field, and on the back of the unit have one of Charm’s pyrolysis units. And instead of letting the waste go to the field, it would be processed on site,” Mba-Wright explained.

In the modeled mobile pyrolysis scenario, the researchers found that the process could generate 5.3 tons of bio-oil and 2.5 tons of biochar for every 10 tons of corn stover. This estimate is slightly lower than the yield of bio-oil produced by other pyrolysis methods but is still reasonable.

The process of taking each feedstock from harvest to well plugging was carbon negative, the scientists found. Switchgrass had the highest carbon footprint at −0.62 kilogram of carbon dioxide (CO2) to kilogram of oil, and oriented strand board had the lowest carbon footprint at −1.55 kilograms of CO2 to kilogram of oil. Corn was in the middle, weighing in at −1.18 kilograms of CO2 to kilogram of oil.

An Array of Economics

Modeling indicated that the new pyrolysis process would be economically feasible as well, costing between $83.60 and $152 per ton of CO2. (The monetary difference accounts for the costs of including biochar sequestration.) These costs fall within the range of carbon credit commodity price ranges.

“The most important message is that there’s an economic case for carbon removal,” Mba-Wright said.

The scientists admit that to many individual farmers, however, this economic case might not seem like a bargain: The base capital cost of each pyrolysis unit would be $1.28 million.

“My impression was they were looking at this from the firm perspective, not exactly the farmer perspective,” said Sarah Sellars, an assistant professor of agricultural economics at South Dakota State University. “A base capital cost of 1.28 million? No farmer would invest in that. If they were going to spend $1.28 million, they’d probably buy more land.”

Mba-Wright said that although the costs are, indeed, significant, there are different options to consider. “Farmers could lease the equipment,” he suggested, adding that businesses could offer a lease-to-own option. “There are also intermediate solutions,” he added, “where you may have a unit that’s shared among farms.”

He acknowledged other challenges as well. Farmers “have a tight schedule during harvesting and planting. They may not want to have to operate another piece of equipment, so that’s something that suppliers of the unit will have to develop: a system that is easy for the farmer to use.”

Life Is Messy

On paper, sequestering carbon while halting fugitive emissions from orphan wells looks like a slam dunk.

But carbon and climate are complicated. “We can look at things from theory and economics and carbon mitigation, but then when it comes to these other variables, like the policy and the infrastructure to implement them, I think we should be cautious,” said Sellars. “Unfortunately, a lot of scientists don’t like to hear that, though. I mean, that’s why economics is called a dismal science.”

Lauren Gifford, director of the Soil Carbon Solutions Center at Colorado State University, agreed, adding that “a lot of what we’re reading in articles and things are promises or goals, but the industry just hasn’t taken off enough for us to see how these things play out at scale. A lot of what we see now is either hope or plans, and we know that real life is messy.”

—Sarah Derouin (@sarahderouin.com), Science Writer

Citation: Derouin, S. (2025), How might leftover corn stalks halt fugitive carbon?, Eos, 106, https://doi.org/10.1029/2025EO250378. Published on 8 October 2025.

Text © 2025. The authors. CC BY-NC-ND 3.0

Except where otherwise noted, images are subject to copyright. Any reuse without express permission from the copyright owner is prohibited.