Inside a cavernous 1930s-era warehouse on the northern edge of Brooklyn, the ancient and all-but-extinct art of stone carving is having a 21st century rebirth. This is the new headquarters of Monumental Labs, a quirky but audacious startup that is combining the meticulous chisel-and-hammer craft of stone carving with the prowess, speed, and efficiency of robotics and artificial intelligence.

Using an $8 million round of venture capital funding, the 2-year-old company is turning this aging warehouse into a modern stonecutting factory capable of quickly producing highly detailed decorative facades, museum-grade marble sculptures, and towering stone monuments. And if founder Micah Springut gets his way, the company will soon be trying its robotic arms at an even grander project: reinventing the way buildings get built.

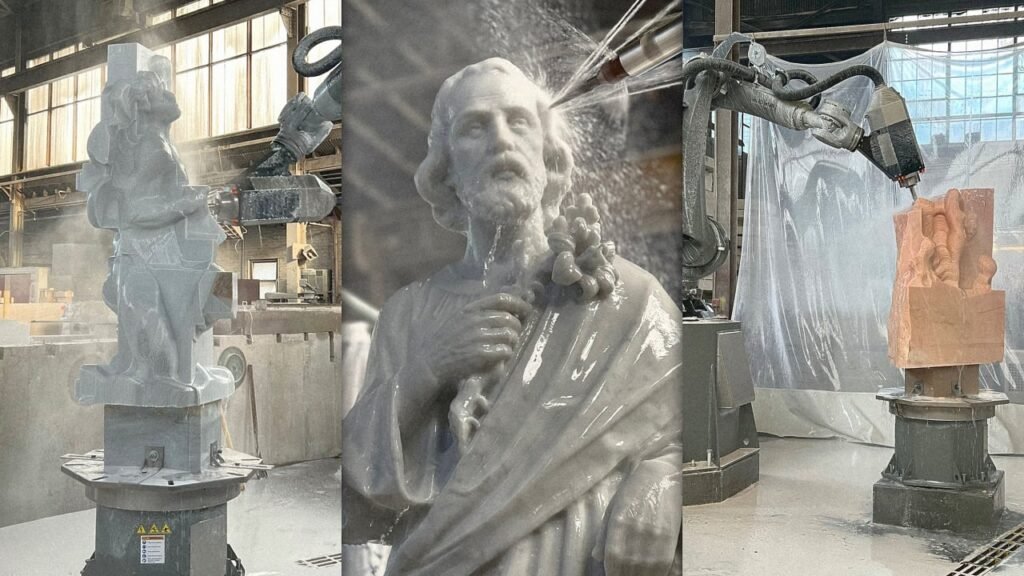

Walking through the warehouse on a recent day, Springut shows off the 30-foot-high ceilings of the main fabrication floor, where more than a dozen seven-axis robotic carving arms will soon be chipping away at massive blocks of granite, limestone, and marble, turning them into towering sculptures and statues. When the 37,000-square-foot facility comes online in the fall, Monumental Labs will begin fine-tuning its stone carving process to quickly and affordably produce structural stone that can be used to build everything from private homes to multi-level apartment complexes.

It will be a big step up from the space Monumental Labs currently leases outside of New York City. That’s where the company produced its first significant projects, including restorations of decorative stone adorning Carnegie Hall and the Frick Museum, which are mostly cut by robots and then hand-finished by trained stone carvers. It’s a process that can cut delivery times for sculptures and decorative facade treatments from months to weeks. But in its current location, Monumental Labs has only been able to deploy two robots, and its monument carving capacity tops out at 12 feet.

“We can’t do an entire facade, we can’t do an entire building, we can’t do a monumental arch,” Springut says of the existing workshop. Behind him in the new factory, SUV-sized slabs of marble sit idly by, waiting for the robotic arms to be installed and activated. “All of that kind of stuff, large-scale works, both public and private, could be done here now,” he says.

The new factory space and capacity is made possible by the $8 million funding round, which was led by Seven Seven Six, Reddit cofounder Alexis Ohanian’s venture capital fund. Founding partner Katelin Holloway, who led the deal with Monumental Labs, says the company offers a perfect blend of technology and humanity. “They’re bringing craftsmanship back to architecture,” she says. “This technology has massive potential to transform how we build cities, bringing back that artistic magic we almost lost.”

Springut says the new space will help the company keep up with growing demand. It’s currently working on several large-scale sculpture projects for private clients, decorative stone facades, and a set of gargoyles that will be added to a new building at an undisclosed university in the South.

The big goal, though, is getting into structural stone. These are giant, Lego-like blocks of stone that are precisely cut to form thick and strong building bases and walls. With a lower embodied carbon footprint and a much longer lifespan than concrete, structural stone is seen as an environmentally friendly alternative construction method. It’s also one humans have relied on for millennia. “We basically built with stone for all of history until about 110 years ago when industrialization came and changed what became efficient to build with,” says Springut. “The cost of fabricating stone, cutting it, and shaping it into the form you want became far, far more expensive than doing that with concrete.” Robotics and automation, he says, will dramatically lower that down to as little as 25% of the cost of building with concrete.

The future of structural stone

Andrew Lane can’t wait. He’s an attorney and prospective developer based in Austin who has become obsessed with the idea of using structural stone to develop new buildings—partly out of frustration with the aesthetics of modern buildings and partly because stone buildings have such longevity. Standing on his balcony in downtown Austin, he pans his phone’s camera from the Renaissance revival-style Texas Capitol Building to the new glass-and-steel office and residential towers a few blocks south. “America could rise, America could fall, that capitol building ain’t going anywhere. That office building right there, that glass, that’s gone in 70 years, max,” he says. “I just don’t understand why we want to build cities like that.” He’s hoping to change course by building townhouses or apartments in Austin using stone carved by Monumental Labs, but is waiting to learn more about exactly how much it will cost.

Springut says that’s still an open question. Monumental Labs has other developer clients who are eager to get started, but everyone first wants to see what the company can produce with its new fabrication space. That’s why one of the first projects Monumental Labs will work on once its new facility is up and running is a 30-foot-tall observation tower built out of structural stone and constructed right in the corner of its main fabrication hall. Springut says that should be enough to get some of these developer clients to commit to building. “We’ve got a number of clients who are just ready for us to be ready,” he says.

There’s still plenty that’s needed before Monumental Labs is actually ready, though. The biggest hurdle is refining the technology behind its stone cutting ambitions, and training its own AI systems to handle the now largely manual process of understanding the cutting paths and the tool heads needed to turn a multiton chunk of limestone into the building blocks of a townhome.

“We’ll be using reinforcement learning to effectively come up with the optimal toolpaths to see a 3D model, and based on the curvature and the geometric forms, to choose what are the right tools, or what are the right angles of attack,” Springut says. “And when we do that, that’s what’s going to bring the cost of fabricating stone down by 80% to 90%.”

The company’s proprietary software, he says, will learn from every carving project its robots undertake, getting better over time. This new facility will be part of building that institutional knowledge, using its new fleet of robots to crank out up to 100 life-sized sculptures per year, and possibly a few full-sized buildings.

But that will have to wait until the robots can actually move into the building. First, Springut says, the 1930s-era complex needs some upgrades, including a reinforced foundation capable of handling the weight of the stones to be carved. Before Monumental Labs can revolutionize the world of building, it’ll have to bring its own headquarters into the 21st century.