Mass Market Appeal

It’s the late 1980s, and Toyota has spent most of the past decade building a reputation around reliability, efficiency, and no-nonsense engineering. Their practical, simple, and durable cars routinely outlasted the European and American competition of the era, and usually with much lower running costs. This made cars like the Corona, Cressida, Corolla and Camry extremely popular among families and commuters who just needed an affordable, no-frills automobile that was built to last.

Going Premium

While Toyotas were considered the smart and sensible choice, absolutely nobody ever called them fun, exciting, or luxurious. Chairman Eiji Toyoda wished to change this perception and, while the company was churning out practical cars for average consumers, had something special brewing behind the scenes for years — a top-secret project, simply codenamed Circle F. The F stood for Flagship, and it was Toyota’s no-expense-spared crack at creating a flagship luxury sedan to challenge the likes of Mercedes-Benz and reinvent how the world saw Toyota. Finally, in 1989 and with everything in place, it was decided that the time was right to take the conservative Japanese brand upmarket with the launch of a dedicated luxury division. And so Lexus was born, and the world was introduced to the outcome of the Circle F project — the 1989 LS 400, and at its heart, a compact and extremely refined V8 engine.

Creating the LS 400

The Circle F project was initiated in 1983, when Eiji Toyoda laid out the ambitious mission to take on the European and American brands that dominated the international luxury car market at the time. A massive team of over 4,000 engineers, designers, technicians, and other professionals, led by Chief Engineer Ichiro Suzuki, took on the challenge. The goal: build the world’s finest luxury performance saloon that, while being opulent, comfortable, and imposing, would also be quieter, faster, more fuel efficient, and more aerodynamic than any rival. This demanded a cabin noise level of under 58 dB at 60 mph with a top speed of at least 155 mph, fuel efficiency of 22.5 mpg, and a drag coefficient of no more than 0.29. The team also had to develop an engine from scratch — one that could achieve these top speed, refinement, and economy targets, while preserving Toyota’s reputation for reliability, longevity, and engineering excellence.

Toyota

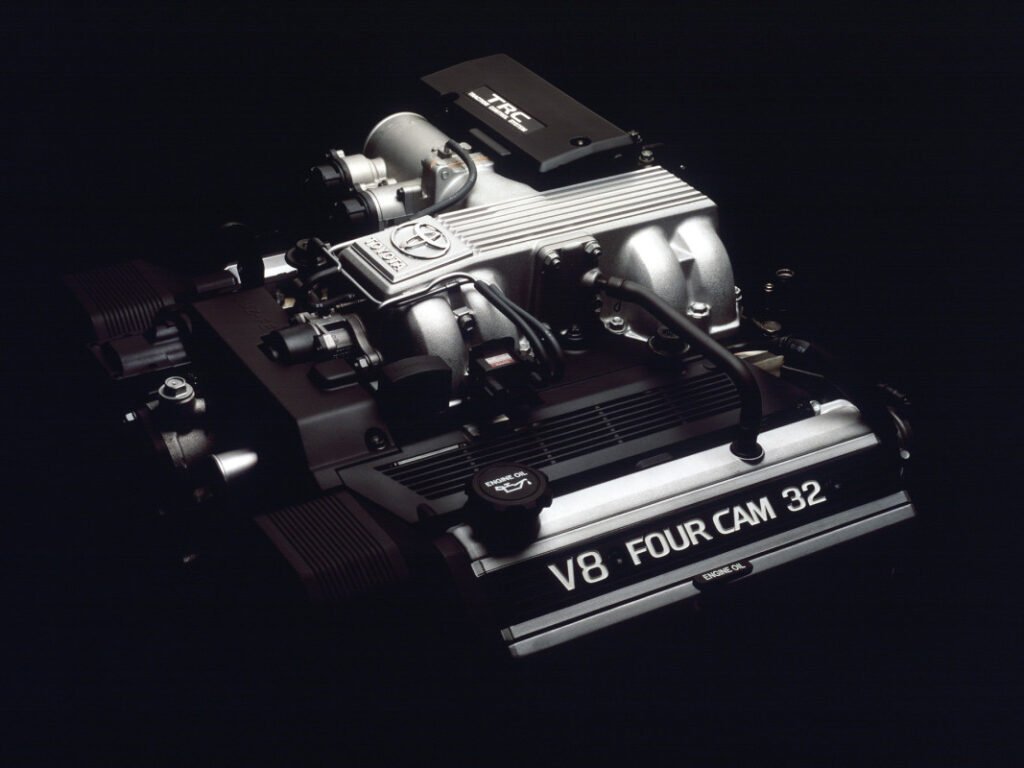

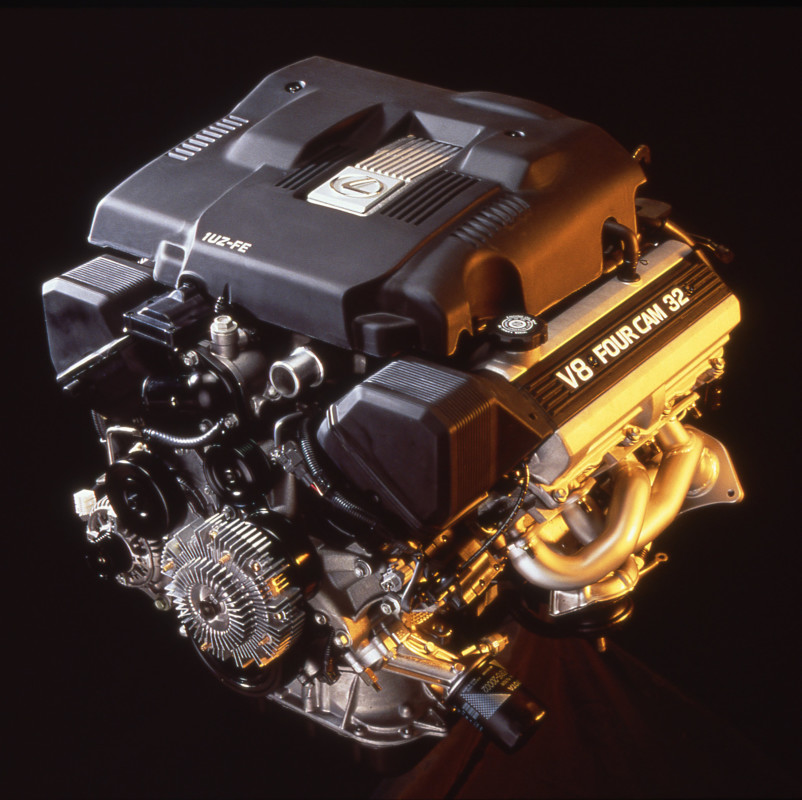

Powering a Flagship

Creating an engine for a new flagship is a formidable task, especially for a luxury sedan designed to ferry the rich and powerful in absolute comfort. Rather than a sporty, high-revving powerplant, the job called for a relaxed, unstressed motor that could effortlessly propel the large car forward on a smooth wave of torque with minimal drama, noise, or vibration. After testing various engine layouts, the development team finally settled on a naturally-aspirated, all-aluminium, 4.0-liter quad-cam V8 with a 10:1 compression ratio that made 260 lb-ft of torque and 250 horsepower at a relaxed 5,400 rpm. They called it the 1UZ-FE.

Equipped with this engine, the LS 400 was extremely well-received at its launch in late 1998, proving to be faster, quieter, smoother, and more fuel-efficient than the competition. All the hard work over the last six years had finally paid off; Toyota’s new flagship was an instant hit. The 1UZ-FE engine has since risen to legendary status as one of the most reliable engines of all time, regularly crossing 200,000 miles with minimal maintenance, with some examples recording over a million miles without major issues.

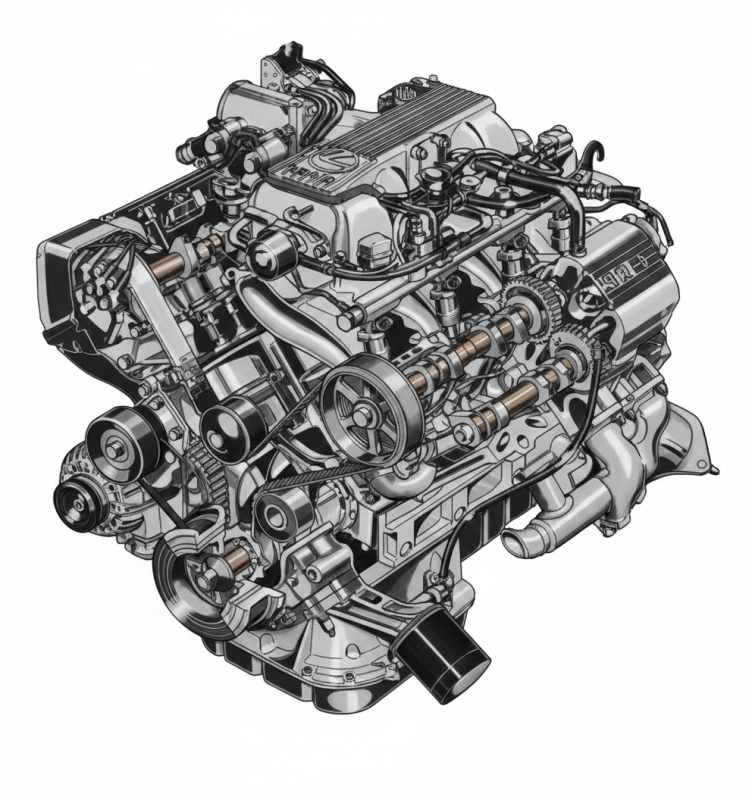

Inside the Unkillable Engine

The secret to the 1UZ-FE’s longevity lies in its ethos; minimising internal stress, vibration, friction, heat, and noise to create one of the smoothest and most refined automobile engines ever built. The robust block features a 90-degree angle between cylinder banks and is topped with two aluminum heads with a total of 32 valves. The aluminum alloy pistons are engineered for minimal thermal expansion, with fine grooves in the skirts to aid lubrication and reduce friction, while connecting rods are forged steel.

The crankshaft, also constructed of forged steel, has eight rather than the customary six counterweights for finer balance, while each of the main bearing caps has four vertical bolts holding it in place, with an additional two cross-bolting the cap directly to the block for added rigidity — something that was only ever seen in very high-performance or race engines. In fact, it was revealed in 2007 by the then president of TRD, that the lower-end architecture of the 1UZ-FE was based on the design of a Toyota motorsport engine that ultimately never saw the light of day.

While the bottom end of the engine may have had its roots in Toyota’s race projects, and is sturdy enough to handle a lot more power than the motor was making, the heads are another story, with most components designed more for efficiency and midrange torque than outright power. Valves are of average size with a narrow included angle while camshaft profiles are conservative, with mild duration and lift on both intake and exhaust. The engine got a small bump in compression to 10.4:1 in 1995, taking peak horsepower up to 260 and peak torque up to 270 lb-ft, while the incorporation of VVT-i in 1998 again raised output to 290 hp and 300 lb-ft.

Tuners Delight

The 1UZ-FE’s relatively unstressed nature, its extremely robust construction, and precise machining tolerances are chiefly responsible for its reputation for reliability and longevity. This, along with the conservative head design, also makes it the ideal candidate for modifications. It didn’t take tuners long to realise that this compact and lightweight V8 had the potential to make massive power, and could easily be swapped into smaller, more nimble cars than the large, unwieldy LS 400.

youtube.com/@d4a

With a healthy amount of torque delivered in an extremely predictable and linear manner, the 1UZ-FE soon became a favourite among the drifting crowd, who discovered how easy it was to maintain long, smooth powerslides with this motor powering their lightweight, rear-wheel-drive, drift builds. Tuners were soon swapping the 1UZ motor into everything from Toyota GT86s and Subaru BRZs to Mazda Miatas, and even choosing this motor over the traditional 2JZ-GTE straight-six for their Supras.

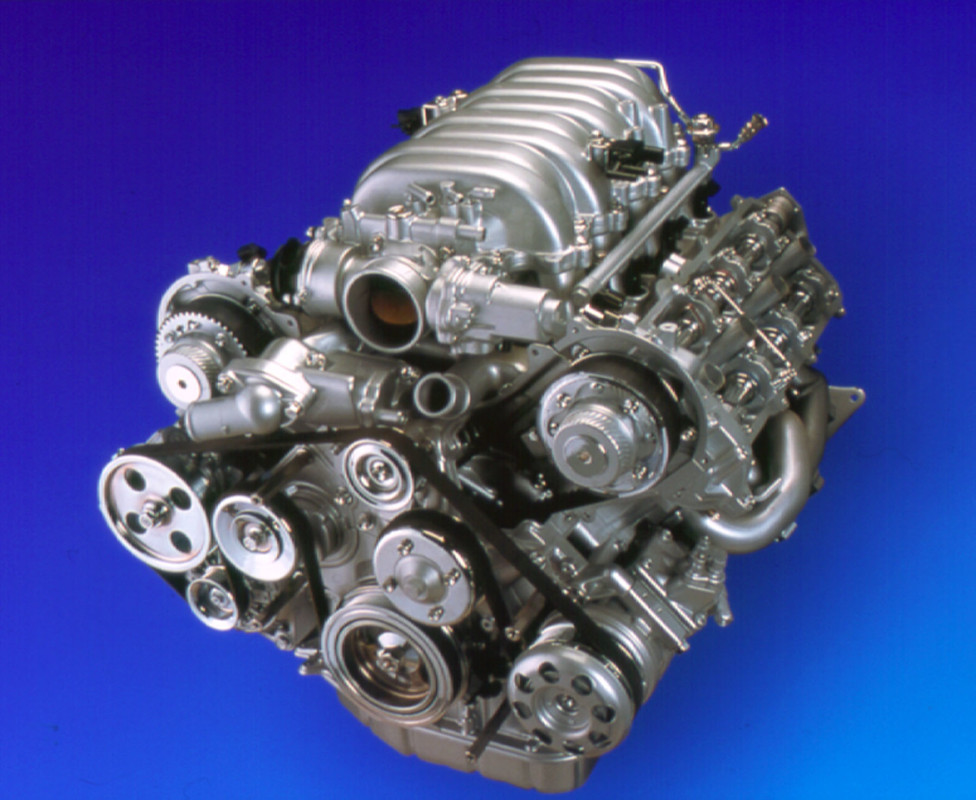

With its extremely overbuilt, race-derived bottom end and restrictive, economy-tuned breathing, the 1UZ-FE also offered enthusiasts a strong base with the potential to make massive power. Just a tuneable, standalone ECU, free-flowing exhaust manifolds, and a cold air intake could bump power up by around 20 to 30 horsepower. Top end modifications such as porting and polishing the heads, altering the valve included angle, installing aggressive camshafts and stiffer valve springs, and replacing the restrictive stock intake with individual throttle bodies greatly free up breathing. While the stock engine had a 6,000 rpm redline, tuned motors were soon revving up to over 8,000 rpm and making over 400 horsepower with stock internals, while still retaining their rock-solid reliability.

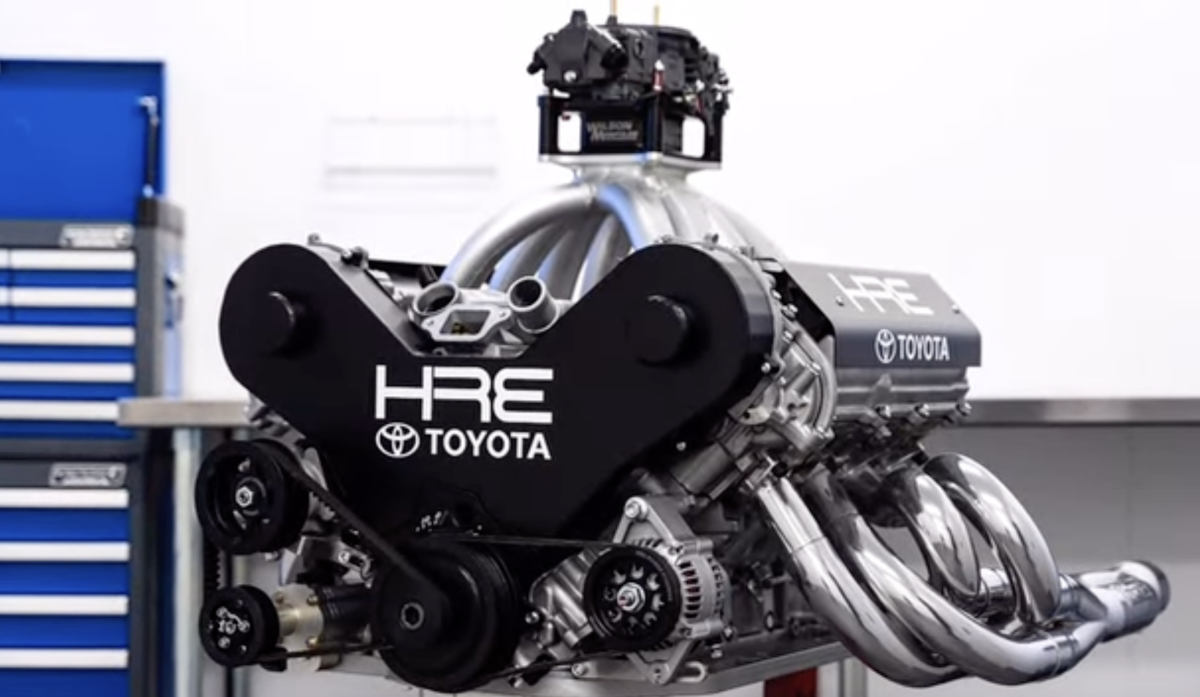

youtube.com/@hughesracebuilt

While the 1UZ-FE could easily make over 400 horsepower by going the naturally-aspirated route, that strong bottom end could also handle large boost pressures without breaking a sweat. Tuners have incorporated turbocharging, supercharging, and even nitrous in their 1UZ builds, pushing power output up to 500 to 700 hp for street builds. Race and drag builds, on the other hand, are a lot more extreme as reliability doesn’t matter, and top tuners have extracted over 2,000 horsepower from completely built 1UZ motors.

More Than Just a Car Engine

In the decades since its introduction, the 1UZ-FE has proven to be one of the most versatile V8s Toyota has ever built. Blending refinement, toughness, and adaptability, this engine has gone beyond traditional roles, being certified for use in light aircraft and marine applications, where reliability is critical. It still commands respect after all this time, having inadvertently gone from a quiet flagship engine to a timeless performance icon.