Nissan has come up with an idea that may enhance the performance, safety, and off-road capability of EVs, so obvious, it’s a wonder it hasn’t been patented before. A new document filed with the United States Patent and Trademark Office, first noted by CarBuzz, aims to apply the idea of active engine mounts to the battery pack in an electric vehicle, turning the massive weight disadvantage of an EV from a drawback into a means of better controlling the chassis. EV batteries can weigh thousands of pounds, and this new Nissan patent wants to shift the balance of that weight as required, thus potentially improving traction, chassis control, and overall efficiency. Let’s take a closer look.

Nissan’s Patent Uses EV Battery As a Counterweight

Nissan

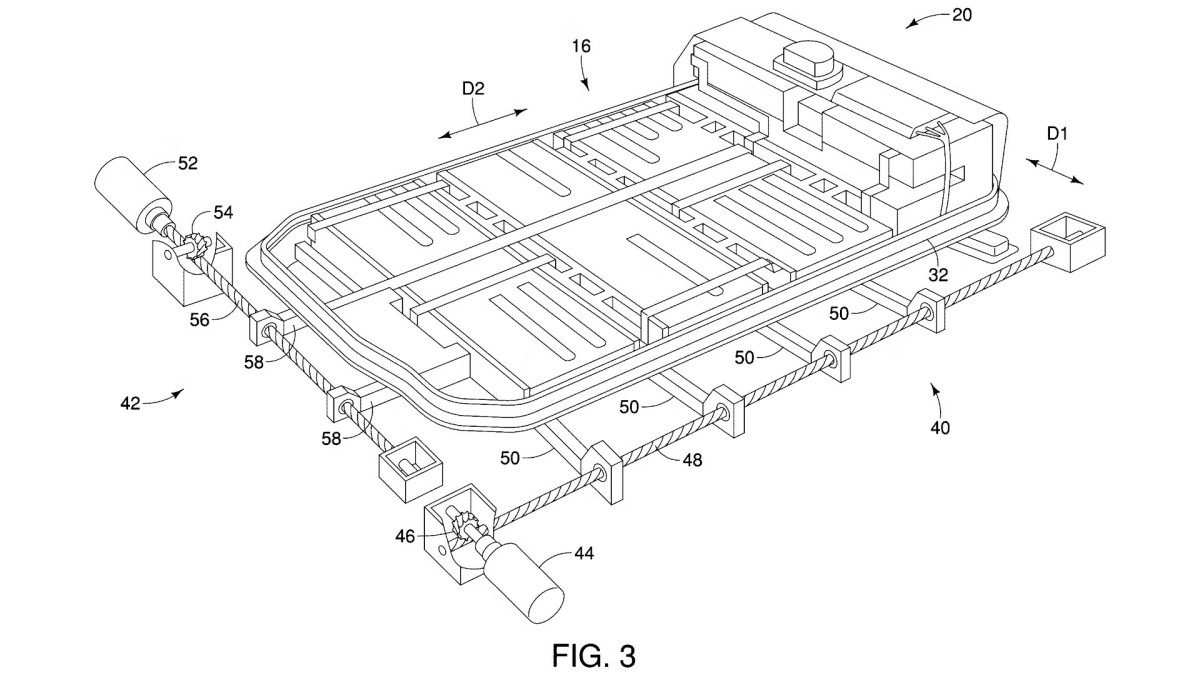

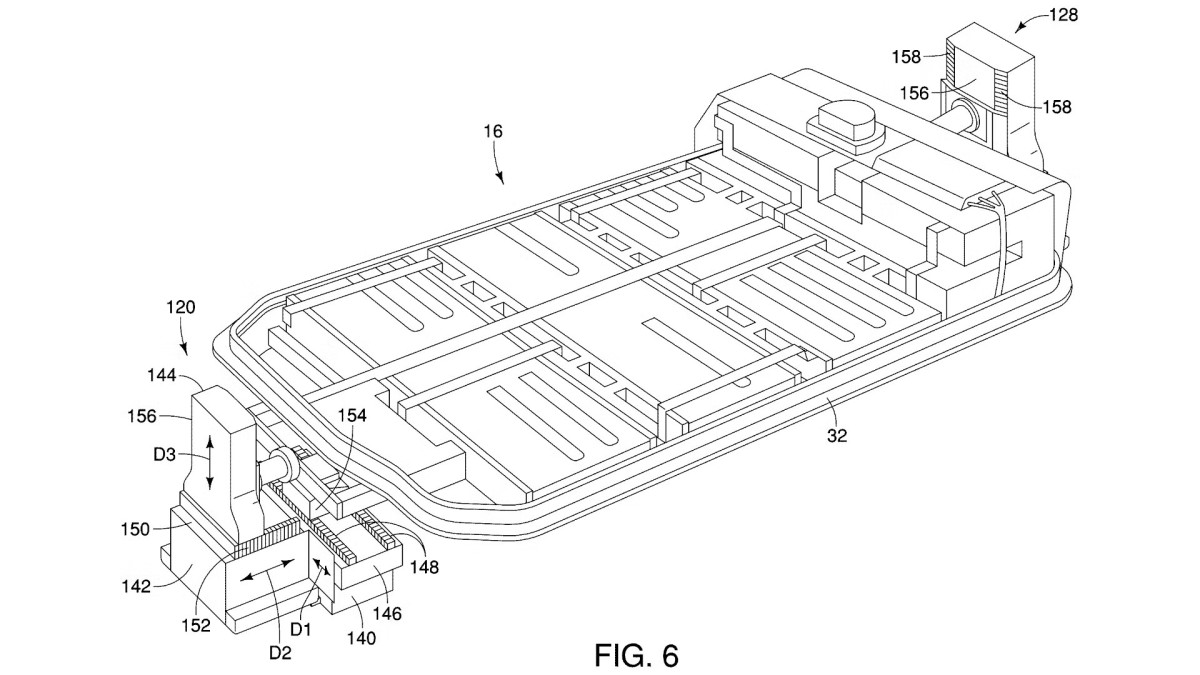

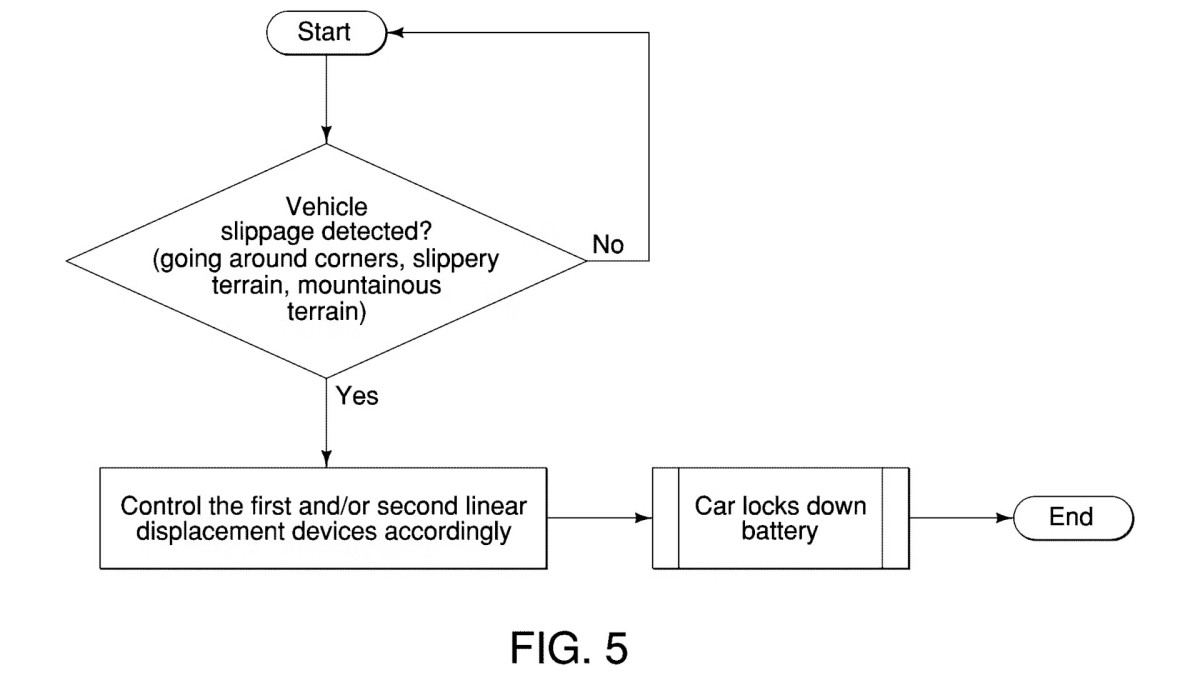

Most EV battery packs are mounted rigidly, and many are fully integrated into the chassis as a structural component of the vehicle, but Nissan envisages mounting the battery pack into a battery tray that is connected to the chassis through actuators. These actuators would be capable of moving the battery pack left and right (along the x axis) or fore and aft (along the y axis), and possibly even a combination of the two axes. To determine how best to actively distribute the battery pack’s weight, the system would have a central computer being fed with data from weight sensors (whether on a vehicle with leaf spring or air suspension), still and video cameras, sensors for pitch, yaw, and acceleration, gyroscopes, radars, and/or other sensors, including ultrasonic, infrared, and acoustic sensors. Many of these sensors would already be equipped as part of driver aids.

Essentially, anything that helps the car understand its surroundings and how the vehicle is being used would be drawn from, and the central processor would determine if and how the weight balance of the vehicle would need to be adjusted, with the aforementioned actuators pushing the battery tray into the optimal area. The patent notes a user interface, implying that the system could behave differently depending on the drive mode, though any actual battery tray movement would be processed automatically.

Benefits and Drawbacks of Nissan’s Active Battery Mount Patent

This idea could help a high-performance vehicle (like a future GT-R, for example) squat on launch to improve traction and acceleration, with the weight balance moved to a more neutral position at higher speeds to improve aerodynamics. When the vehicle is aggressively turning to the right, the battery tray could shift to the inner side of the EV, helping maintain balance and reduce understeer, and when braking heavily, the battery tray could shift backward to keep the car flat and reduce the risk of a front lock-up. On an SUV, the vehicle’s weight could be shifted to the side that is at risk of lifting to prevent a rollover, and when such a vehicle is towing a heavy load up a steep hill, the weight could shift forward to improve traction. Similarly, the weight of a pickup’s fully loaded bed could be counteracted, and in the event of an accident, the battery tray could move away from the impact, albeit very slightly. However, there are a few issues with this patent.

Cost and complexity are obvious stumbling blocks, and packaging would be a problem, too. The system would take up space that could be used for battery cells or room in the cabin, and it would surely take a lot of energy to continually move something as heavy as a battery pack, reducing efficiency. That said, the idea of a constantly shifting center of gravity shows promise, and as solid-state batteries have begun to enter production, they could counter the above problems with less mass and smaller footprints.